SERVICES

Idea Consultation

Being involved in your specific industry allows us to turn our deep understanding of your customer into stand out products.

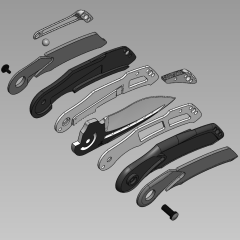

3D Models

The cornerstone of modern design and manufacturing, 3D models serve as the basis for a variety of other services.

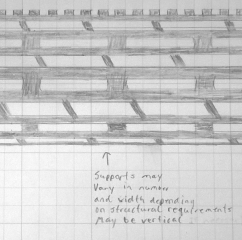

2D to 3D

If you work best by putting pen to paper, or have legacy drawings without CAD, we can use your 2D documents as a guide to build 3D models.

Reverse Engineering

If you have physical parts, but no documentation, no problem. Send us a sample and we will measure it to generate models and other assets.

Stress Simulation

Using FEA analysis, we can simulate forces on your design to help ensure it will stand up to a lifetime of use or trim excess weight while still maintaining necessary strength.

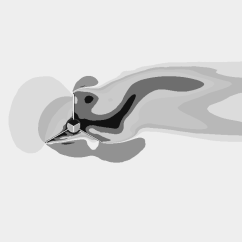

Fluid and Thermal Simulation

Our computational fluid dynamics (CFD) software allows us to evaluate the flow or thermal characteristics of a design, so we can optimize materials and geometry for the desired effect.

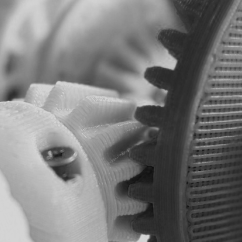

Prototypes

Todays 3d printers and traditional prototyping techniques can give you an early preview of your design, allowing you to evaluate, experiment, and quickly make improvements.

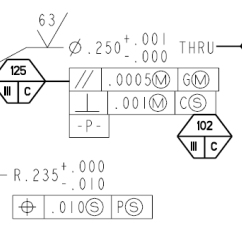

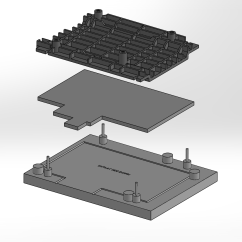

Tolerance Scheme Analysis

Combining modern tolerancing techniques and intricate part relationships, these calculations often make the difference between parts assembling smoothly and piles of scrap and rework.

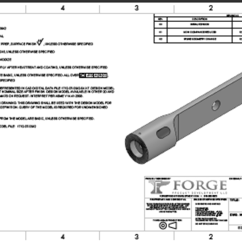

Technical Drawings

These documents will capture the information of your 3D design into a format that is more easily used in manufacturing. They fully define the limits of your product, including material specifications, dimensional tolerances, and other process details.

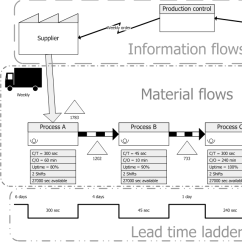

Lean Implementation

The analysis that goes into producing value stream maps, product wheels, and kanban systems in complex manufacturing environments can be daunting, but invaluable when it comes to freeing up capital and reducing waste.

Work Holding Design

These fixtures grip raw material inside machine tools to allow for fast and accurate manufacturing. Not only can we help design the tooling, but the process as well.

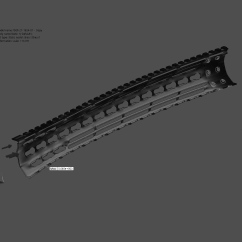

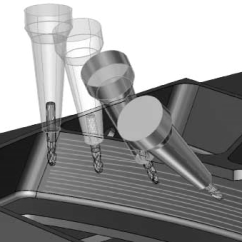

Models for CAM

Todays top manufacturers use CAM software to quickly program accurate, efficient tool paths, but to perform at their best, they need to pull geometry from 3D models.

Workstation Design

Properly designed work environments can not only reduce manufacturing costs, but they can also reduce inventory, lead time, employee fatigue, and space requirements.

Tooling for Assembly

On the factory floor, where saving seconds on a single operation can save hours over the course of a year, even a simple jig or fixture can be worth thousands of dollars.

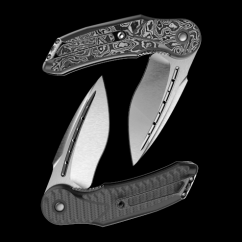

Photo Rendering

Used in marketing, and to make design decisions, these super high quality images are generated entirely from the 3D models, months before traditional product photos could be taken of a physical prototype.

CONTACT US

Copyright © 2018 Forge Product Development LLC

This site is protected by reCAPTCHA and the Google

Privacy Policy and Terms of Service apply.